Infrastructure

State-of-the-Art Manufacturing Facilities

Advanced Pressure die casting

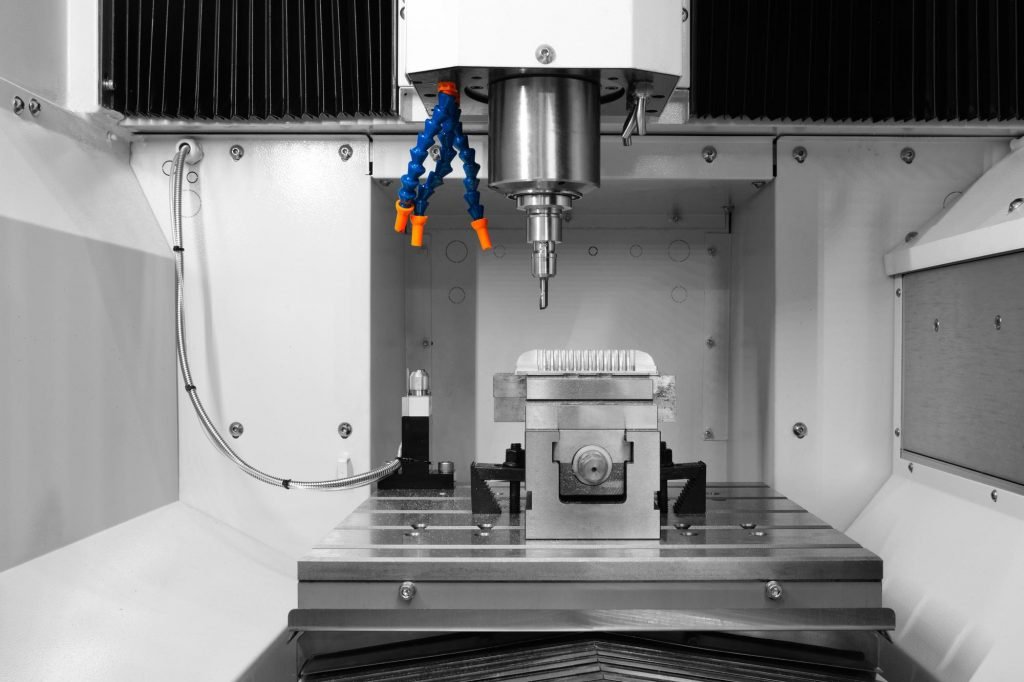

Precision CNC Machining & Automation

Quality Inspection and Metrology

We follow a stringent quality control process supported by world-class metrology tools. Our labs feature CMMs (Coordinate Measuring Machines) with Renishaw probes for high-resolution measurements. We use MAHR Surface and Contour systems for surface inspection. Height gauges, bore gauges, slip gauges, and profile projectors form our basic inspection arsenal. All tools are regularly calibrated and traceable to NABL standards. First Article Inspection (FAI) and Statistical Process Control (SPC) are integrated into our process. We maintain controlled environments for inspection to avoid temperature-based variations. Visual checks and functional tests are part of our final quality stage. Our goal is zero-defect delivery with 100% customer satisfaction. Quality is the foundation of everything we do.

COMMON QUESTIONS

Most Popular Questions

We operate three dedicated manufacturing units located in Ambattur Industrial Estate, Chennai. Each plant is designed for specific operations including die casting, machining, and quality inspection to maintain operational efficiency and focus.

Our die casting infrastructure includes cold chamber pressure die casting machines ranging from 200T to 400T. These machines are integrated with PLC controls, automated spraying, and shot monitoring systems to ensure dimensional accuracy and repeatability.

Our CNC infrastructure is powered by machines from Brother, Fanuc, and MAZAK, offering advanced turning and vertical machining capabilities. These are equipped with features like tailstocks, tool life monitoring, and automation for consistent output.

We have a full-fledged metrology lab equipped with Coordinate Measuring Machines (CMM), MAHR Surf Contour machines, digital gauges, and profile projectors. All instruments are calibrated and traceable to NABL standards, supporting our zero-defect commitment.

Yes, all our manufacturing units follow ISO 9001 and IATF 16949 certified quality management systems. Our infrastructure is routinely audited and upgraded to comply with both customer and international standards in automotive and industrial sectors.